Application Stories - OpenCNC System Development Platform (Episode I)

2021-02-19

mktadmin

OpenCNC system development platform is composed of an open and reconfigurable hardware platform and software platform. It is based on the WinCE operating system and meets the requirements of the CNC system for real-time, security and stability. The development platform adopts Googoltech's gLink-II protocol to realize the interconnection and intercommunication of production line equipment, and provide customized processes and algorithms. The CNC system development platform supports machining codes generated by various CAD/CAM software such as MasterCam, AutoCAD, UG, etc. It is widely used in compound machining centers, engraving and milling machines, precision engraving machines, drilling and tapping centers, glass sweeping machines, high gloss machines and other fields.

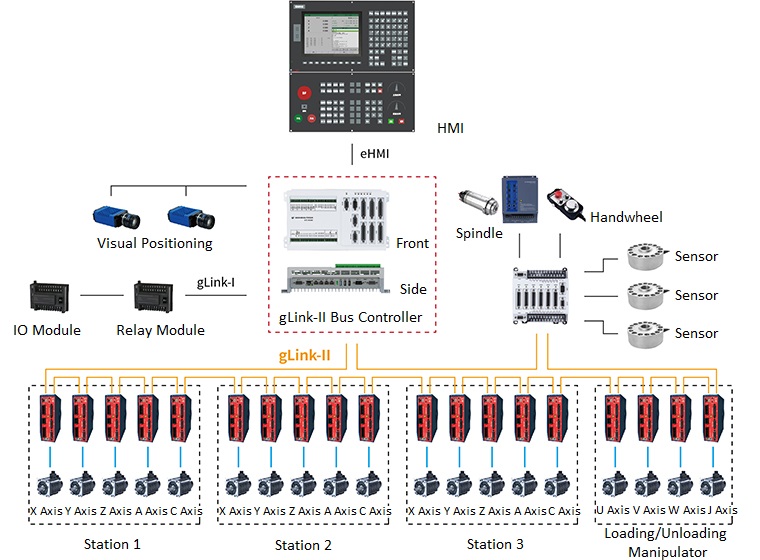

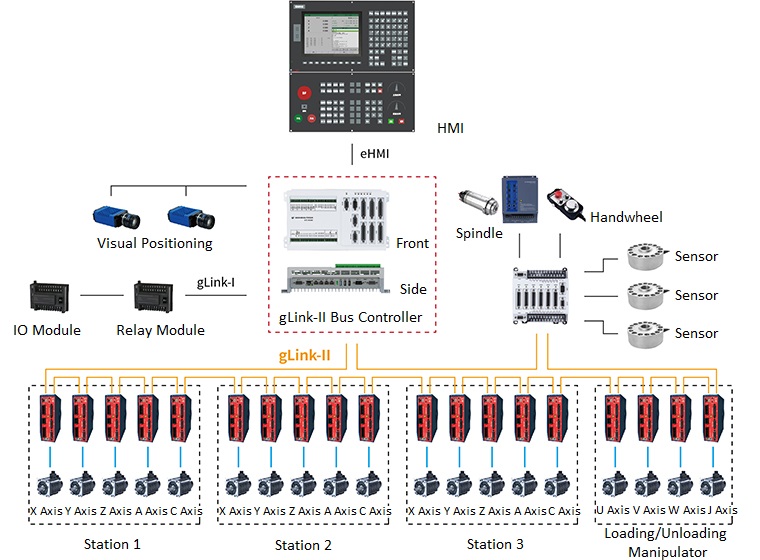

A. Multi-Channel Grinding CNC System

With the rapid development of the 3C industry, there is an increasing demand for surface grinding of curved metal frames, glass, ceramics and other parts. The multi-channel grinding CNC system is based on Googoltech's gLink-II protocol, which interconnects force position control, multi-axis linkage, and multi-channel information in real time, and solves the control process problems of compound processing equipment. The system can collect force sensor data in real time during grinding process and carry out force control compensation. At the same time, the system has multiple processing coordinate systems, which can be processed in parallel and improve the processing efficiency. When processing complex workpieces, there is no need for multiple clamping and repositioning, which significantly improves the processing accuracy.

Features:

● High Integration: Integrate three-channel grinding equipment, manipulator, and visual positioning in one.

● High Precision: Reduce the times of workpiece clamping and improve the precision.

● High Efficiency: Multi-channel simultaneous processing.

● Force Control Compensation: Each channel has pressure detection to compensate position deviation in real time.

● Tool Wear Automatic Compensation Function.

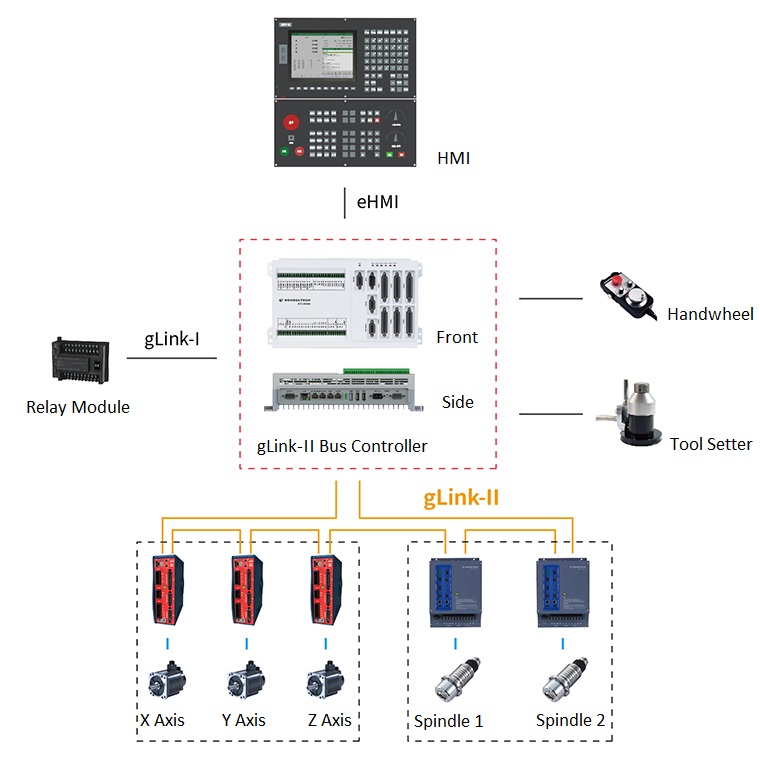

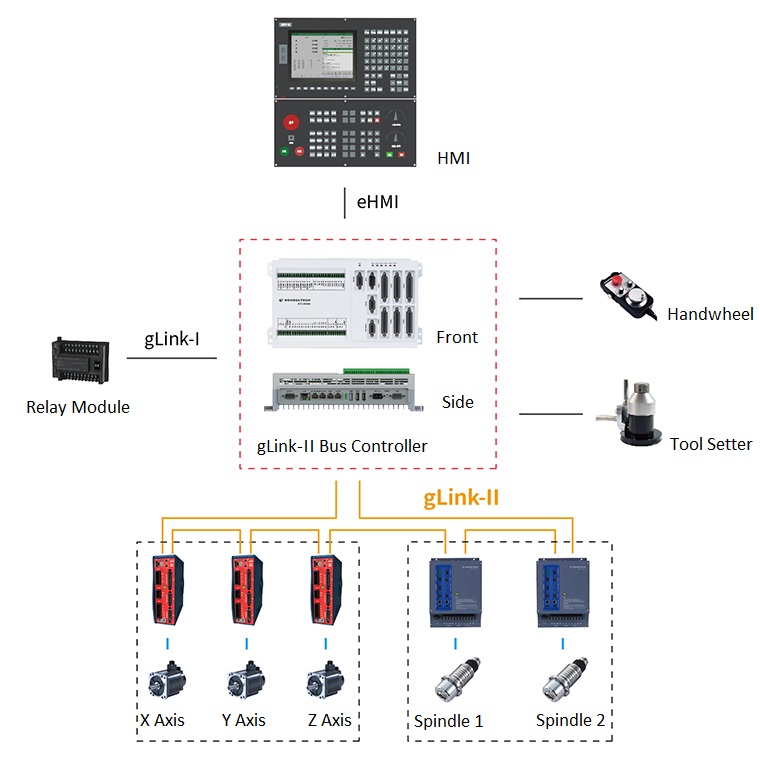

B. Wheel Hub Machining

The wheel hub is an important safety component of the load-bearing vehicle. Its accuracy, fatigue strength, appearance, etc. are all important performance indicators. Its intrinsic quality determines the stability, maneuverability and comfort of the vehicle during driving. The OpenCNC system development platform specifically optimizes the trajectory and speed for wheel hub machining, and improves machining efficiency and machining accuracy. Customized dedicated CAM software can import 3D models and automatically generate machining codes. At the same time, the CNC system development platform combines with the Googoltech’s Cloud platform to provide customers with personalized customization.

The system provides special CAM software for the wheel hub, which is easy to operate and use. It improves the processing efficiency while improving the surface finish of the wheel hub.

Features:

● Trajectory Optimization: Trajectory optimization for wheel hub processing to improve efficiency and surface finish.

● Speed Optimization: Use control algorithm for speed optimization.

● Vibration Suppression Function: Advanced vibration suppression control algorithm to ensure stable operation of the machine.

● Special CAM for Wheel Hub: According to the wheel processing technology, import the model and automatically generate the machining code.

● Personalized Customization: Combined with intelligent management and control software to achieve personalized customization of wheels.

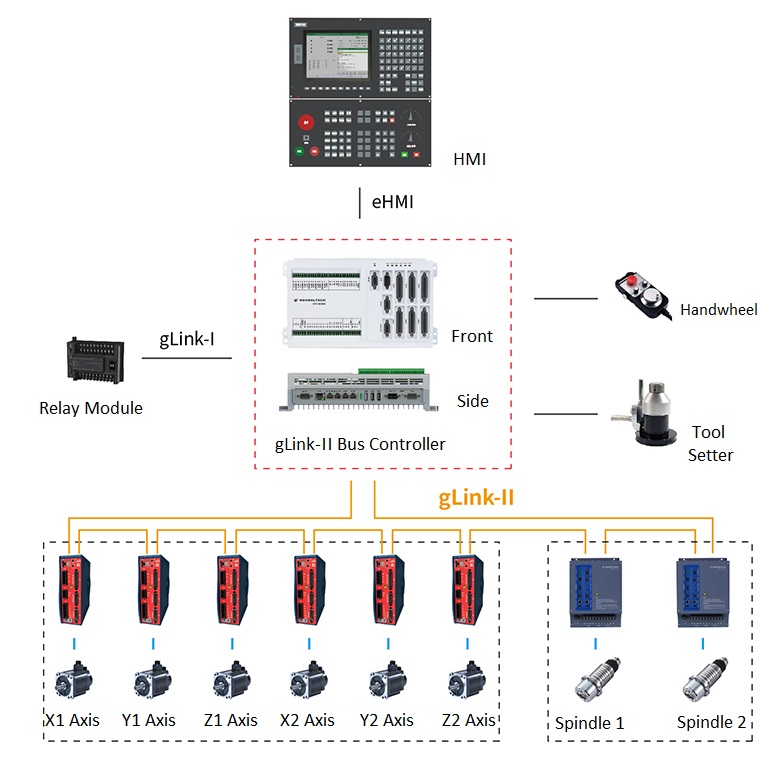

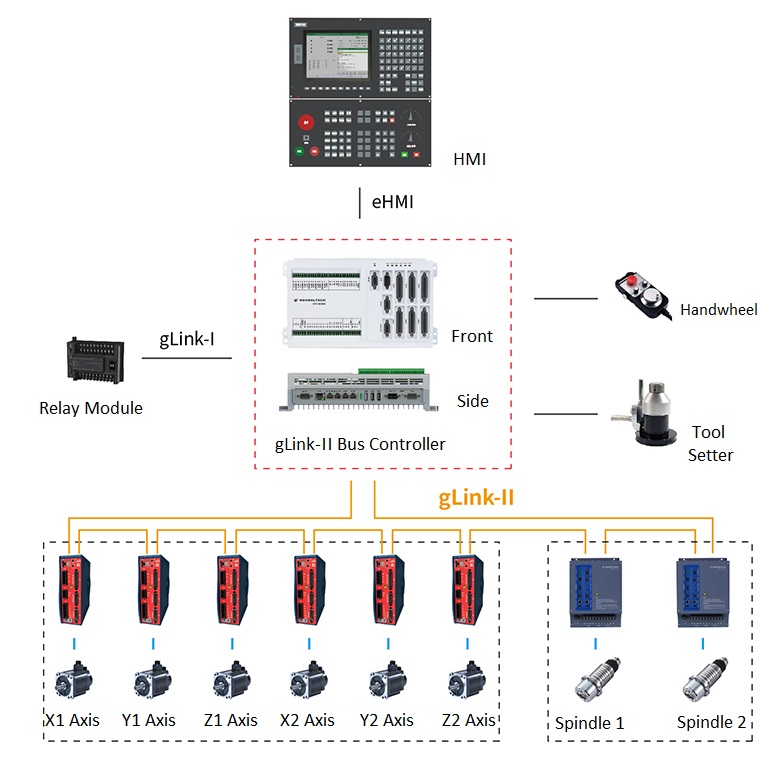

C. Dual-Channel Dental Carving Machine

People's awareness of health and the pursuit of beauty have attracted more and more attention to dental and oral health. Dental carving machine, as a kind of equipment for repairing and modifying teeth, and carving out accurate, perfect and clean dentures, has an increasing market demand. However, there are some problems in the processing process of dental carving machine, such as brittle materials, easy edge collapse, a large number of small line processing and so on. The OpenCNC system development platform is specially designed for tooth processing path optimization to improve processing efficiency. The optimized speed planning and vibration suppression function can avoid edge collapse in the processing process.

The dual-channel dental carving machine improves the processing efficiency, and the surface of the processed teeth is smooth and without lines. Combined with the intelligent control software, it simplifies the communication process between the hospital and the production workshop.

Features:

● Path Optimization: Path optimization for tooth processing to improve efficiency.

● Speed Optimization: Use control algorithm for speed optimization.

● Vibration Suppression Function: Advanced vibration suppression control algorithm to ensure stable operation of the machine.

● Intelligent: Combine with intelligent management and control software to simplify the process.