Process Flow

Calibration operation before processing: calibration (visual, weighing, air pressure, height measurement, temperature control, etc.)

● Teaching data or importing data.

● Safety detection (temperature control, air pressure, etc.)

● Feeding material

● Visual positioning

● Height measurement (enabled when the vertical height of the machining plane differs greatly.)

● Dispensing (continuous dispensing, single point dispensing, dispensing volume, patching, etc.)

● Discharge

Main Features

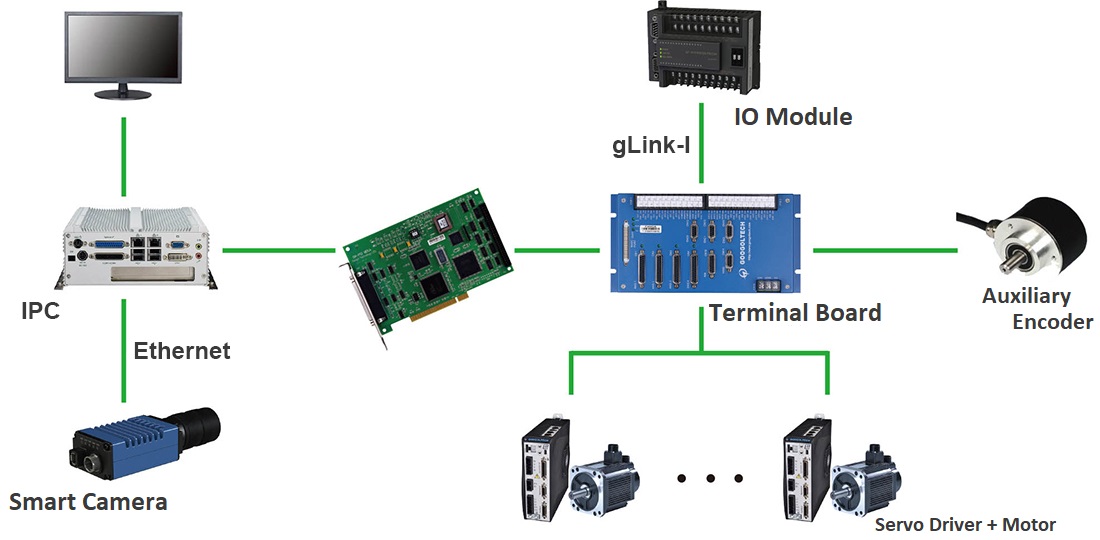

● Support multi-axis linkage, move according to data track, and have speed optimization function;

● Support flying camera;

● Precise control of the dispensing head and support for multiple dispensing modes;

● Support encoder feedback, can be extended to full closed-loop control, support the use of linear motors;

● Support more than 50 IO inputs and more than 20 IO output controls;

● The repetitive point accuracy is within 0.01mm, and the maximum speed can reach 1m/s;

● Support non-axis analog input/output and peripheral connection.

System Advantage

The dispensing speed is fast, the glue quantity is accurate, the position is accurate, and it meets the industrial requirements of the 3C industry.